Introduction:In the dynamic landscape of manufacturing, success stories emerge when innovation meets precision. Allow us to take you on a journey through the triumphs of our Dish End Pressing Machine—a revolutionary solution that has redefined dish end forming. Before we delve into the intricacies, let's explore a real-life success story that underscores the impact of this exceptional machine.

Success Story:

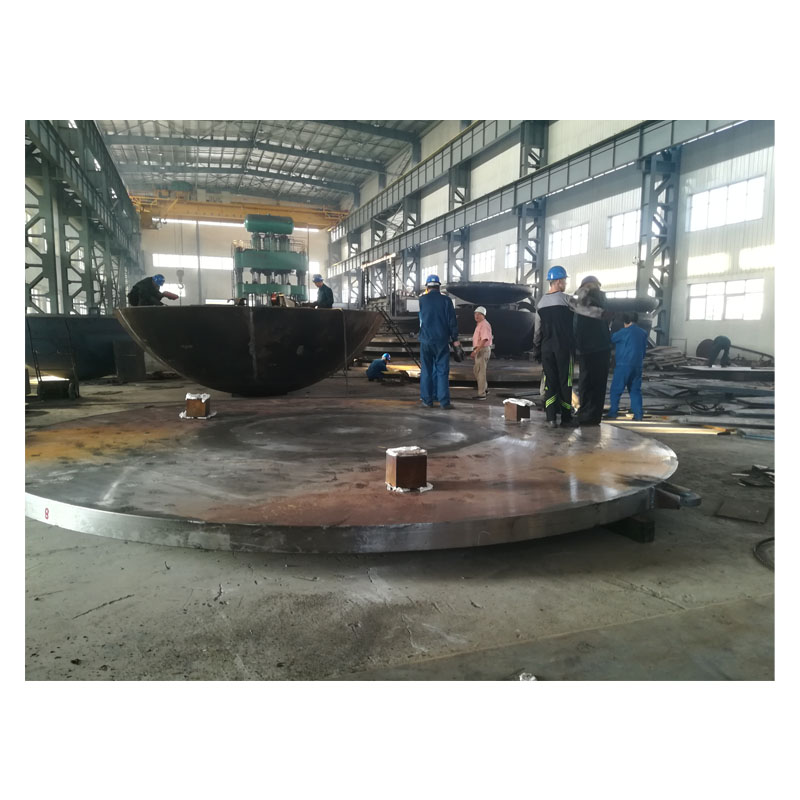

In the heart of a bustling manufacturing facility, challenges were abundant. The demand for precision in dish end forming seemed insurmountable, with intricate designs and stringent quality requirements. That's when our Dish End Pressing Machine stepped in, ready to change the game.

Facing the need for a reliable solution, a renowned pressure vessel manufacturer turned to our machine. The goal was clear: enhance efficiency, ensure precision, and elevate the overall quality of dish end production. The design of our machine, allowing seamless parameter setting and automated processes, caught the attention of the manufacturer.

The pressing process, once a manual and labor-intensive task, transformed into a streamlined operation. The programming-free functionality eliminated complexities, while the reliable positioning and safety features provided a level of trust previously unmatched. The steel welded frame ensured durability, and the easy-to-operate interface significantly reduced the learning curve.

The impact was immediate. Production timelines shortened, and the rejection rate plummeted. The Dish End Pressing Machine not only met the requirements but exceeded expectations. The manufacturer experienced a surge in productivity, allowing them to take on more significant projects and expand their market presence.

Now, Let's Dive Deeper:

With this success story as a backdrop, let's explore the working principles, features, and applications that make our Dish End Pressing Machine an unparalleled solution in the realm of dish end forming. From its inception in overcoming challenges to becoming an integral part of success stories, our machine is poised to elevate your manufacturing endeavors.

Working Principle, Features, and Applications:

Working Principle:At the heart of our Dish End Pressing Machine lies a state-of-the-art design. This Human-Machine Interface empowers users to effortlessly set parameters, enabling the automatic execution of translation, rotation, and tilting of semi-finished products. This eliminates the need for manual intervention during the pressing process. The machine boasts programming-free functionality, ensuring reliable positioning, ease of operation, and unparalleled flexibility.

Product Features:Our Dish End Pressing Machine boasts a range of features that make it a standout choice in the industry:

- Steel Welded Frame: Ensures robustness and durability.

- Easy to Operate: User-friendly interface for seamless operation.

- Position Control: Stop at any position, thanks to the integrated limit switch.

- Pressure Management: Equipped with a pressure manometer, pressure valve, and safety valve to prevent overloading.

- Cooling Mechanism: Hydraulic oil cooler for optimal performance.

Material Handling: Includes a mechanical crane for manual material handling.

Why Choose Our Dish End Pressing Machine:

- Precision and Efficiency: The machine ensures precision in dish end forming, enhancing efficiency in the manufacturing process.

- User-Friendly Interface: The design makes it easy for operators to set parameters and control the machine seamlessly.

- Reliability: With features like reliable positioning and safety measures, our machine offers a trustworthy solution for dish end forming.

Distinguishing Factors:In comparison to similar machines in the market, our Dish End Pressing Machine stands out with:

- Programming-Free Operation: Unlike competitors, our machine eliminates the need for intricate programming.

- Versatility: Accommodates various pressing process requirements without manual intervention.

Flexibility: Adaptable to different applications within the sheet metal industry.

Additional Applications of Dish End Pressing Machine:

Pressure Vessels: Our Dish End Pressing Machine is ideal for the fabrication of dish ends used in the construction of pressure vessels. It ensures the highest standards of quality and precision required for these critical components.

Oil and Gas Industry: The machine finds extensive use in the oil and gas sector for crafting dish ends used in the manufacturing of storage tanks, pipelines, and other crucial components. Its efficiency and reliability make it a preferred choice.

Heat Exchangers: In the realm of heat exchanger production, our machine excels in forming intricate dish ends that play a vital role in the efficiency of heat exchange processes. The precision offered by the machine is crucial for optimal performance.

Aerospace Components: For the aerospace industry, where precision is paramount, our Dish End Pressing Machine is employed in shaping dish ends for various components, ensuring a high level of accuracy and reliability.

Food and Beverage Processing: Dish ends produced by our machine are integral to the manufacturing of vessels used in the food and beverage industry. These vessels are essential for processes such as fermentation, brewing, and storage.

Pharmaceutical Equipment: The pharmaceutical sector benefits from the precision and hygiene offered by our Dish End Pressing Machine. It is used in the production of vessels for pharmaceutical processes, ensuring compliance with stringent industry standards.

Renewable Energy Systems: As the renewable energy sector continues to grow, our machine plays a crucial role in forming dish ends for vessels used in the production and storage of renewable energy, such as solar and wind power applications.

Automotive Industry: Dish ends produced by our machine contribute to the manufacturing of specialized containers and tanks used in the automotive industry. These components are vital for various automotive processes, including fuel storage and transportation.

As you embark on the journey to elevate your manufacturing precision and efficiency, remember that success stories like the one above are not isolated incidents. Our Dish End Pressing Machine stands as a testament to the transformative power of innovation. Ready to script your success story? Send us an inquiry and be a part of the revolution in dish end forming!