Opening a door to the world of metal fabrication, we explore the world of tank dish end machine together. In this era of ever-changing technology, Tank dish end machine are gradually coming into the limelight with their unique craftsmanship and highly accurate manufacturing process. Like a palace of precision art, these machines are redefining our perception of metal forming. Let's unveil this engineering marvel together and see how it reveals its endless possibilities in various industries.

The Marvelous Tank Dish End Machine:At the core of metal fabrication's transformation lies the tank dish end machine – a symphony of technology and craftsmanship. These machines redefine precision, seamlessly shaping metal sheets into flawless tank dish ends with unparalleled accuracy.

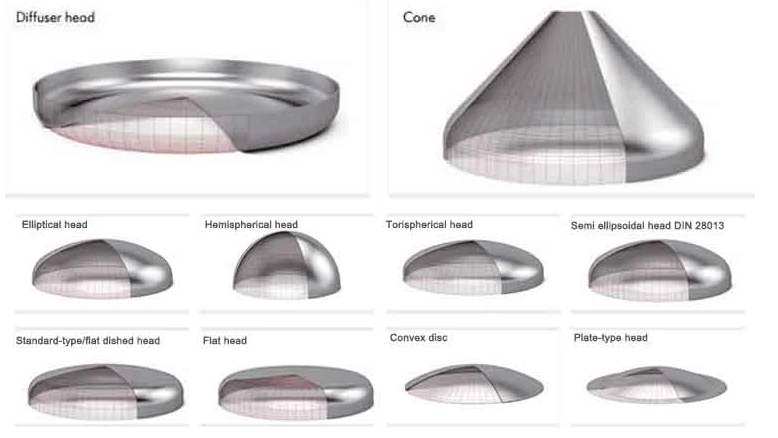

Craftsmanship at Its Finest:More than mere functionality, tank dish end machines are the artisans of metal shaping. Witness the fusion of engineering and artistry as these machines sculpt metal into intricate, aesthetically pleasing forms. It's not just about components; it's about crafting masterpieces that embody dedication to perfection.

Innovation as a Driving Force:In the dynamic world of tank dish end machines, innovation is key. From advanced CNC controls to cutting-edge material handling systems, these machines continually evolve. Manufacturers invest in research and development, ensuring each machine represents the pinnacle of technological achievement.

Diverse Applications:Explore the versatility of tank dish end machines as they become indispensable across various industries. Whether in petrochemicals, food processing, or pharmaceuticals, these machines play a pivotal role in shaping vessels for storing and transporting crucial materials.

With the continuous development and innovation of circular head sealing machine technology, its application scope has been continuously expanded, bringing wider possibilities to various industries. Here are some examples of tank dish end machines expanding their application range in different fields:

Aerospace field: The high-precision manufacturing and excellent material adaptability of the circular head sealing machine make it very popular in the aerospace field. It is used to manufacture key components such as fuel tanks and oxygen tanks of spacecraft to ensure their lightweight and high strength.

Energy industry: In the energy industry, tank dish end machines are widely used to manufacture pressure vessels, boilers, reactors and other equipment. This not only improves production efficiency, but also ensures the safety and reliability of the equipment.

Marine engineering: tank dish end machines can be used to manufacture key components of ocean platforms, such as the spherical heads of submersibles and the shells of seabed exploration equipment. Its corrosion resistance and high degree of sealing make it ideal for marine projects.

Medical device manufacturing: In the medical field, tank dish end machines can be used to manufacture autoclaves, reactors and other equipment. Its controllable shape and size in different environments gives it flexibility in medical device manufacturing.

Environmental protection field: The customization ability of the circular head sealing machine makes it an ideal choice for manufacturing various containers and reactors required in exhaust gas treatment equipment, sewage treatment equipment, and environmental protection projects.

Construction engineering: In the field of construction, tank dish end machines can be used to manufacture various structures such as large water tanks, oil tanks, and gas storage tanks to meet different needs in construction projects.

Food and Beverage Industry: The round head sealing machine can provide highly customized containers for the food and beverage industry to meet the requirements of different food processing and storage and ensure the quality and safety of food.

Transportation: tank dish end machines can be used to manufacture key components in the transportation field such as high-pressure gas cylinders and liquefied natural gas storage tanks, promoting the development of green energy.

With the continuous advancement of science and technology, the application of tank dish end machines will continue to expand, bringing more innovation and benefits to various industries. Through continuous research and development and customization capabilities, tank dish end machines will continue to demonstrate their outstanding value in various fields.

Tailored Excellence:Originality takes center stage as tank dish end machines offer customization. This bespoke approach enhances functionality and adds an element of exclusivity to every project. Embrace the opportunity to bring your unique vision to life through tailored metal shaping.

Embracing the Craft:If you find yourself captivated by the world of tank dish end machines and wish to explore how these marvels can elevate your metal fabrication processes, look no further. Our experts are ready to guide you through the intricacies of selecting the perfect machine for your needs. Contact us today to unlock a realm of possibilities in metal shaping.

In conclusion:

In the journey of metal manufacturing, the circular head sealing machine has set a new benchmark in technology with its exquisite craftsmanship, innovative design and wide range of application fields.

If you have a strong interest in the application of circular head machines, or your project requires customized metal forming solutions, we are ready to provide you with professional consulting services. No matter what industry you are in, our team of experts will tailor the most suitable solution for you based on your needs.

Contact us today to start a new chapter in metal forming together. By cooperating with you, let us witness the infinite possibilities of metal blooming in your hands. Send an inquiry and discover the future of custom metal fabrication!