1. The shape and use of the head of the Hydraulic head stretching machine

The head is the end cap on the pressure vessel, and is a main pressure-bearing part of the pressure vessel. The shape includes spherical, elliptical, dish-shaped, spherical cap, conical shell and flat cover. It is an indispensable and important component in the pressure vessel equipment in many industries, which is related to the long-term safe and reliable operation of the pressure vessel. The material of the head is mostly carbon steel, stainless steel, alloy steel, etc.

2. The processing method of the head of the Hydraulic head stretching machine

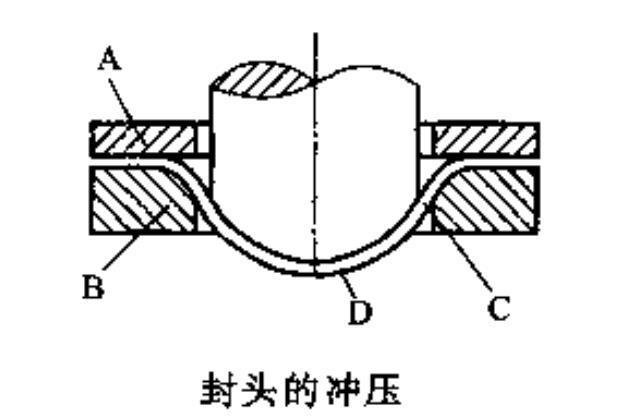

(1) Stamping. To adapt to mass production, to suppress thick-walled and small-diameter heads, multiple sets of head dies are required.

(2) Spinning. Some super-large and ultra-thin heads, especially in the chemical industry, are mostly large and small batches, especially suitable for spinning. The oval head is very suitable for spinning, while the dish head is rarely used, and the spherical head is more difficult to press.

3. Head processing equipment and tools of Hydraulic head stretching machine

(1) Heating equipment. Gas stoves are mostly used in large factories. At present, the heating adopts chamber type or reflective heating furnace, and the fuel oil or gas heating is used as much as possible. The characteristics of the furnace are clean combustion, high efficiency, easy temperature control, not over-burning, and not easy to decarbonize. The heating furnace shall be equipped with a temperature measuring device and a temperature recorder.

(2) There are two types of hydraulic presses for head forming: single-acting and double-acting; there are also two types of hydraulic presses and hydraulic presses. Single-action means only stamping cylinders, no edge-pressing cylinders, and only small and medium-sized factories are using them. Large factories use double-acting, that is, there is a blank holder and a stamping cylinder. The transmission medium of the hydraulic press is water, which is cheap, moves quickly, and is not stable. The transmission medium of the hydraulic press is oil. It is more expensive to change the oil than water once, the transmission is stable, the requirements for sealing are high, the requirements for guiding are high, and the requirements for oil are high. The oil filter is not good or the direction is changed quickly, and the oil circuit is closed. Some actions produce shocks, which make the action of the press unstable. Therefore, it is necessary to filter the oil frequently, change the oil on time, and thoroughly clean the oil circuit and the oil tank when changing the oil.

(3) Use tooling. Various head forming upper and lower dies and feet, etc. (must be checked and accepted according to relevant technical conditions, there should be no pores, shrinkage, slag inclusion, etc., and the geometric dimensional accuracy and curve can be used after passing the inspection).

(4) Common tools. Tightening wrench, sledgehammer, crowbar, steel ruler, tape measure, photoelectric thermometer, internal and external calipers, handling tools, etc.

4. Pressing of the head of the Hydraulic head stretching machine

When pressing, the blank of the head should be placed as far as possible to be concentric with the mold, and the offset between the center of the blank and the lower mold should be less than 5 mm. When pressing with a hole head, it should be noted that the elliptical opening of the blank is aligned with the direction of the long and short axes of the mold. During the pressing process, the manhole punch should be aligned with the opening position of the blank and pushed out slightly higher than the lower mold. At the plane (about 20 mm), then the upper die is pressed down again, and the manhole punch is also dropped at the same time, and the head is pressed into shape. During pressing, the punching force should be slowly increased from small to small, and should not be suddenly increased or decreased.

When the hot stamping head is cooled to below 600 degrees, it can be pulled away from the mold for hoisting, and must not be placed in the tuyere, and more than two pieces should not be stacked before cooling to room temperature. During continuous stamping, the temperature of the die rises to about 250 °C, and the stamping should not be continued. After cooling measures are taken to reduce the temperature of the die, the work can be continued. The perforated head should be formed at one time as much as possible. When it cannot be formed at one time due to the limitation of conditions, attention should be paid to the concentricity with the head when punching the manhole, and attention should be paid to keep the wall thickness at the flange of the manhole uniform.

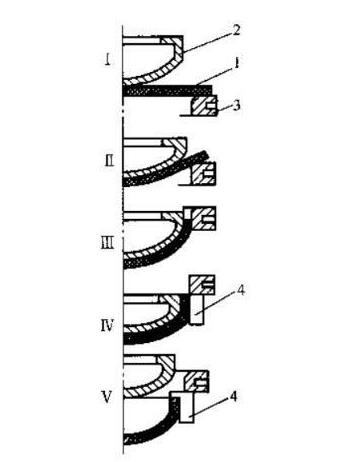

5. The process flow of the cold-pressed head of Hydraulic head stretching machine

The initial position of the hydraulic press of the head → the tension slide and the blank holder are lowered quickly together → the blank holder is lowered rapidly → the blank holder is pressurized → the tension slide moves down and stretches the workpiece → pressure holding delay and pressure relief → Stretch slider and presser slider return → jack up the rotating device to jack up the workpiece → (after the workpiece is removed) jack up the rotating device to return. The ejection start time of the jack-up rotary device can be activated by the position set in the return stroke of the slider, so as to increase the working frequency.

The composition characteristics of the Hydraulic head stretching machine:

1. The head forming hydraulic press is divided into cold-pressing head forming hydraulic press and hot-pressing head forming hydraulic press according to its material and process. The body of the head stretching hydraulic press adopts a four-column or pre-tightening split frame structure. Generally, the head drawing hydraulic press of the formed parts adopts a four-column type, which has a simple structure, is economical and practical, and is guided by the four-column. The head part with high precision requirements adopts a prestressed frame structure and is guided by four-corner and eight-sided plane guide rails, with high guiding precision and strong anti-eccentric load capacity.

2. The stretch head forming hydraulic press and production line are mainly composed of the main engine, the stretching cylinder, the blank holder, the hydraulic system, the electrical system, the lubrication system, the cooling system and other parts. The main machine includes the upper beam, the lower beam, the column, the nut, the stretching slider, the blanking slider, the mobile table, etc. The fuselage is connected by 16 nuts and four uprights to form a closed structure with sufficient rigidity and strength, and the tie rods are tightened by hydraulic pre-tightening to ensure the rigidity of the whole machine.

3. The upper beam is equipped with the main oil cylinder assembly, the stretching slider and the blank holder are installed between the upper and lower beams, the upper plane of the stretching slider is connected with the main oil cylinder assembly by bolts, and the stretching die is installed on the lower plane of the stretching slider. The connecting cylinder is clamped by a quick-change oil cylinder, and the blank holder is installed in the stretching slider, the lower end is connected to the blank holder through a flange, and a quick-change die ring device is installed in the blank holder. The lower beam is equipped with an ejecting rotating device, which is used for ejecting and rotating the oil after the workpiece is stretched. The upper plane of the lower beam is equipped with a moving table and its lifting and clamping device, positioning device, and fitting detection device. The guide of the column and the slider is made of alloy material, which has high hardness, good wear resistance and high guide precision.

4. The power part of the hydraulic system of the stretching head forming hydraulic press consists of three upper and lower oil tanks. The upper oil tank is arranged at the rear of the upper beam or on the top of the upper beam to provide power oil for the equipment stretching cylinder and edge blanking cylinder.

The head stretching machine has a flexible application range for rapid stretching, high production reliability, and economical application.

■ Suitable for hot-pressing head forming

■ The press structure adopts four-column structure

■ Radial moving posts are installed on the blank holder

■ The stroke of the blank holder is adjustable

■ Blank holder force and stretch force can be adjusted automatically

■ Can realize single action and double action separately

If you want to know more information about the Hydraulic head stretching machine, you can contact us directly.