This machine is a kind of special equipment used for bending and shaping of sheet metal. It can roll the cylinder link head and the cylinder link cylinder ideal equipment. It is used in petroleum, chemical, boiler, hydropower, shipbuilding, industrial equipment installation and machinery manufacturing industries. It has a wide range of applications. The lubrication system of the machine adopts manual lubricating oil, and the lubricating oil is connected to each lubrication point. It is small in size, compact in structure and reliable in oil supply, which facilitates the lubrication of equipment and improves the service life of wearing parts. The left and right movement of the main roller is realized by an oil cylinder, and the driving wheel is equipped with deceleration to rotate to drive the cylinder and the driven wheel to move, and the flatness is realized during the extrusion process.

Principle of Rolling

The structure of the machine is two-roller symmetrical. The center symmetrical position of the left roller and the right roller make balance movement, which is obtained through the thread mouth and nut (hydraulic cylinder). The two lower rollers make rotational movement, and the output of the reducer meshes with the right roller to realize the walking of the workpiece. When the downward pressure of the roller exceeds the flexural limit of the material, the rolled material is squeezed at both ends to achieve smooth rolling.

Specification model: 14*2000

Extrusion thickness: 14 mm (workpiece material: carbon steel, stainless steel)

Coil width: 2000 mm

Yield limit: 245 MPa

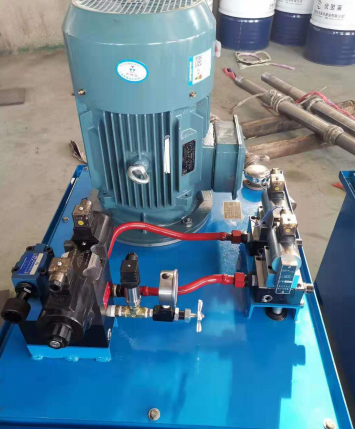

Hydraulic motor power: 2.2 KW

Motor power: 1. 5 KW (frequency conversion)

Rolling speed: 4.6 m/min

Equipment advantages

1. No hammer knocking

2. No noise

3. Improve production schedule

4. Tank flatness 100

5. Reduce labor costs

6. If a worker reshapes the weld, it takes a group of 2 people, and it takes about 2 shaping machines to finish a weld in 5-8 minutes.

The equipment can be operated by one person, saving a lot of labor costs a year.